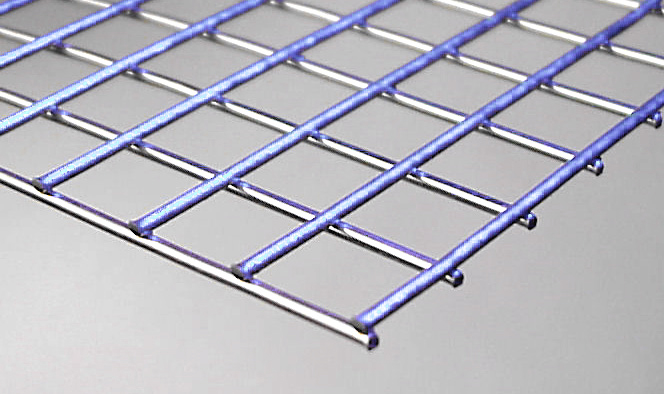

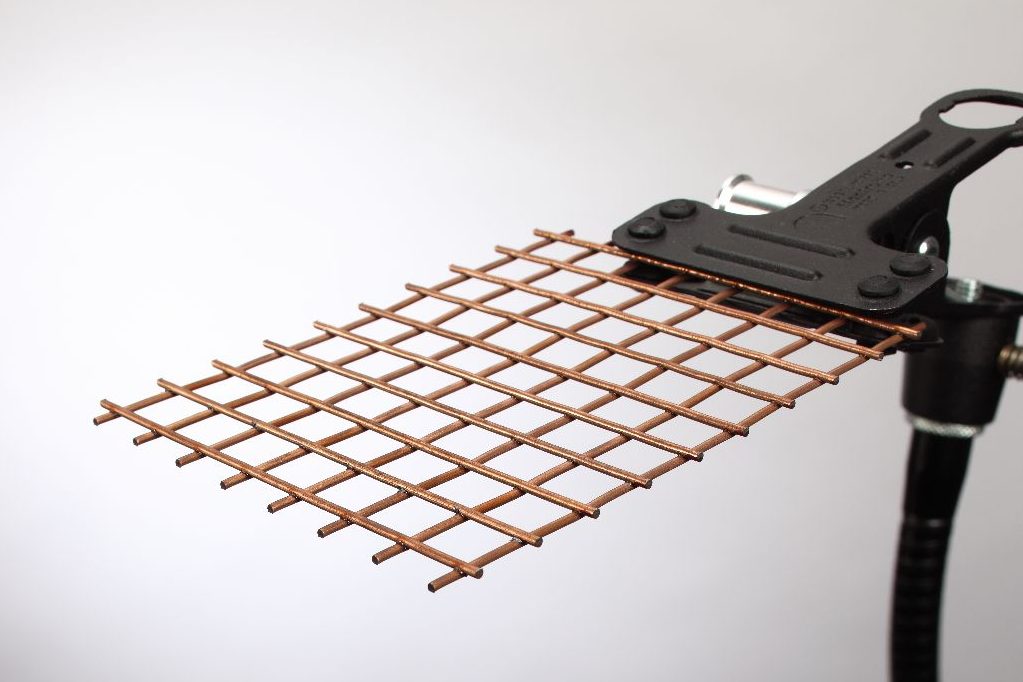

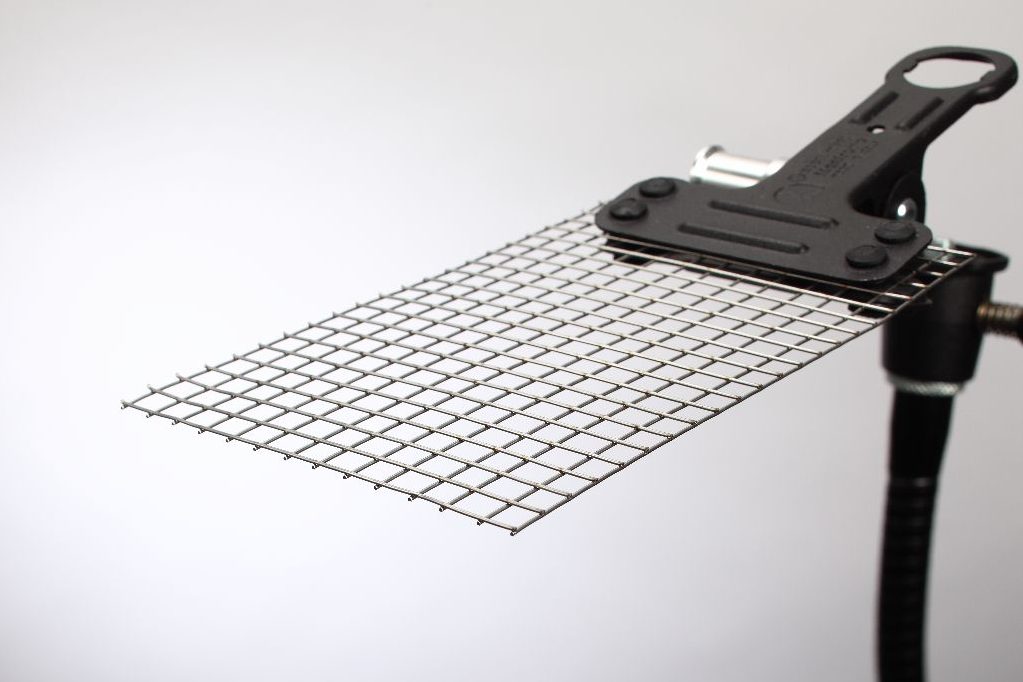

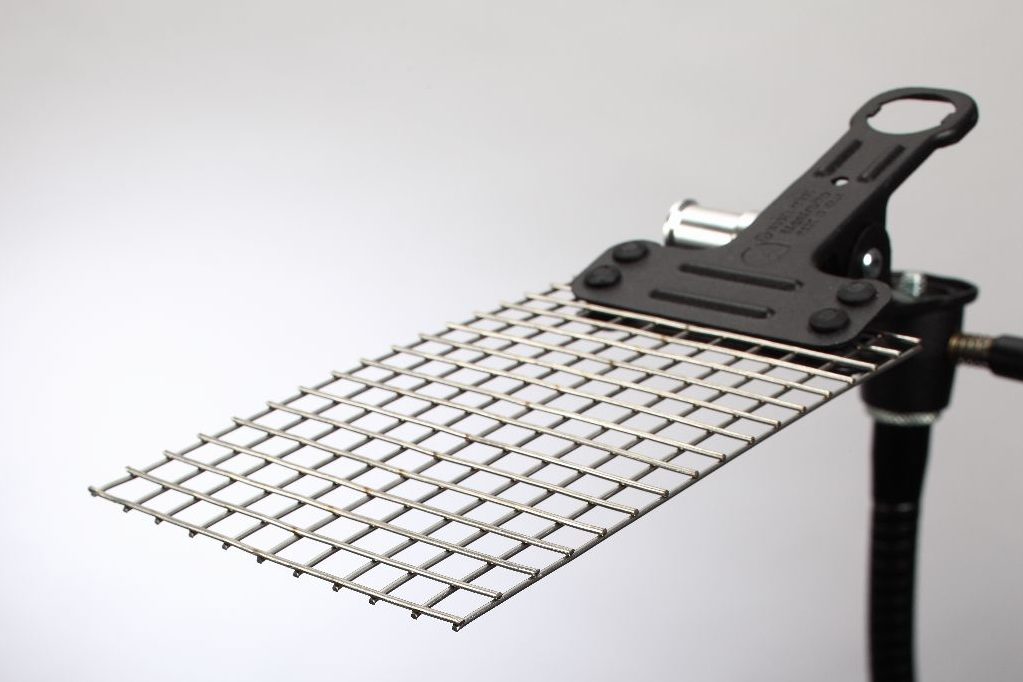

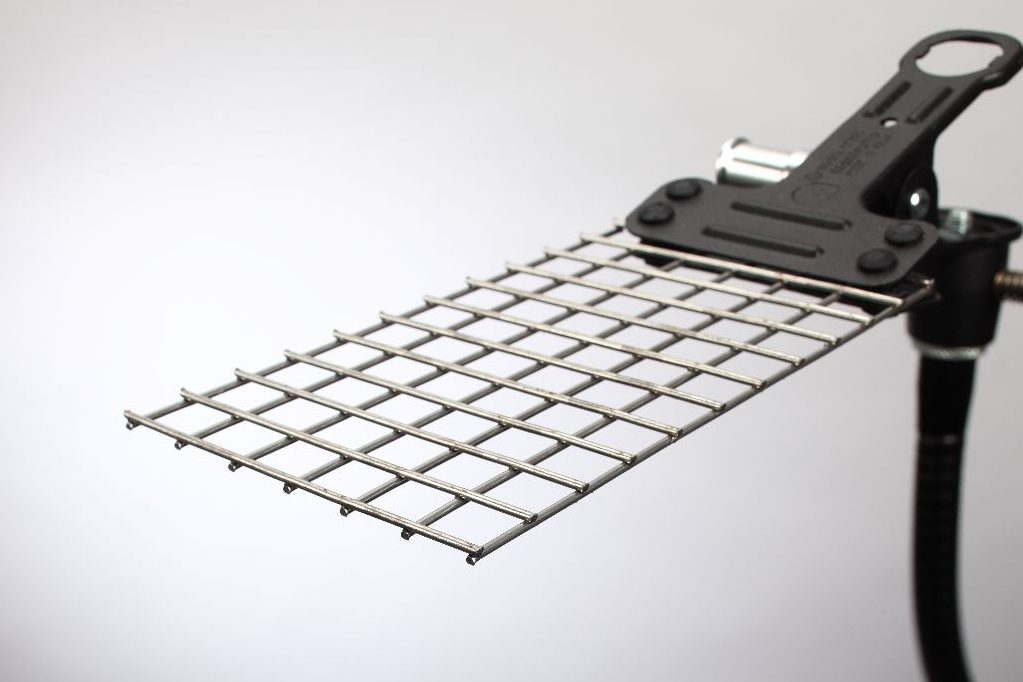

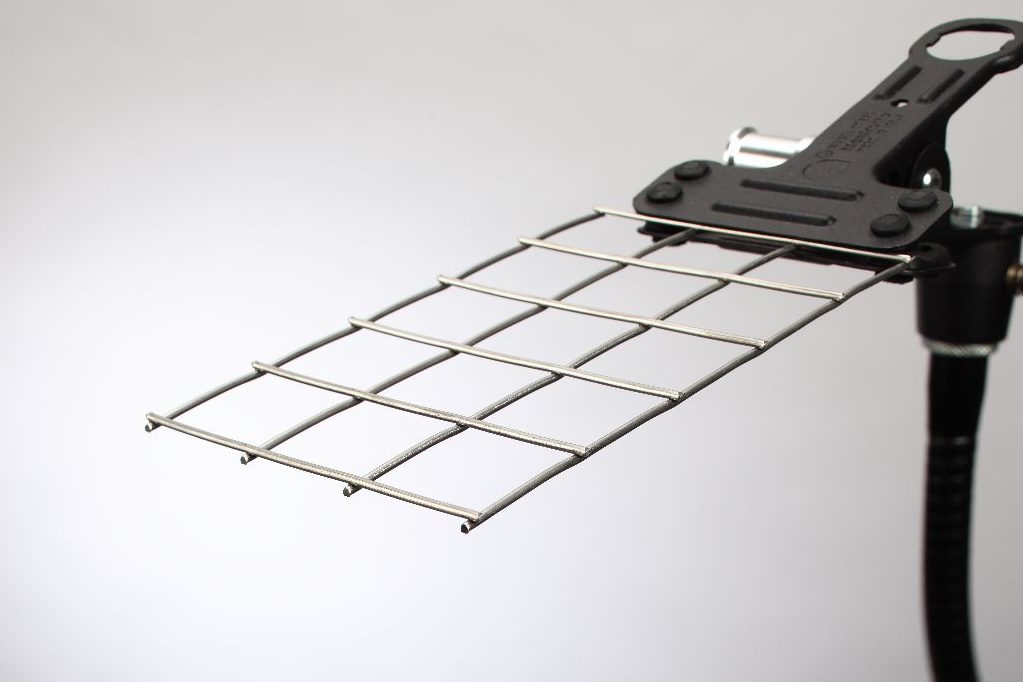

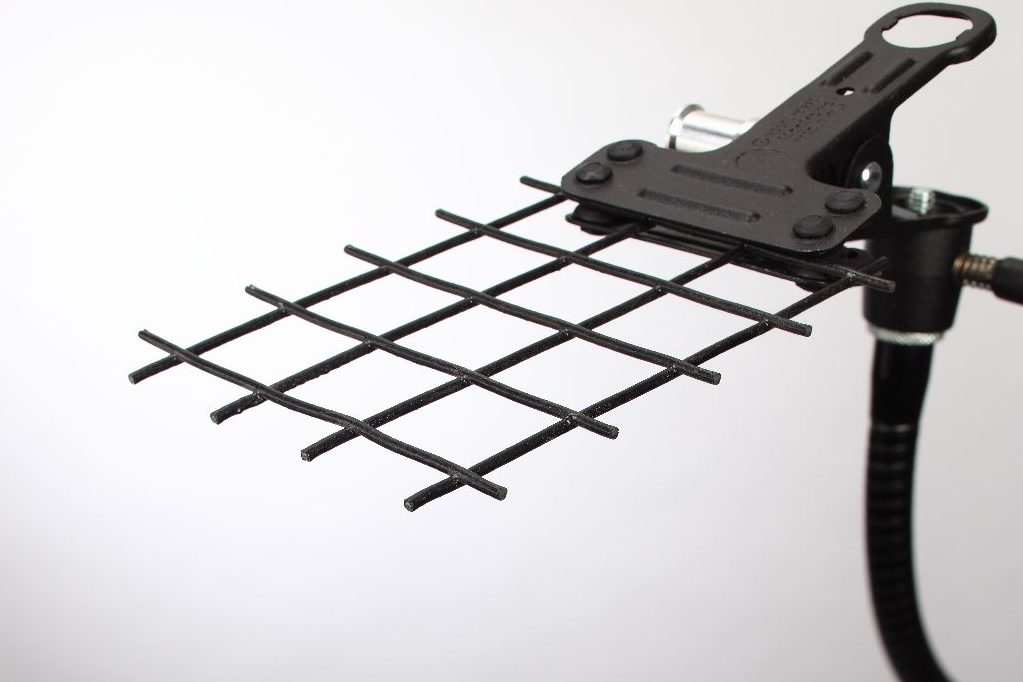

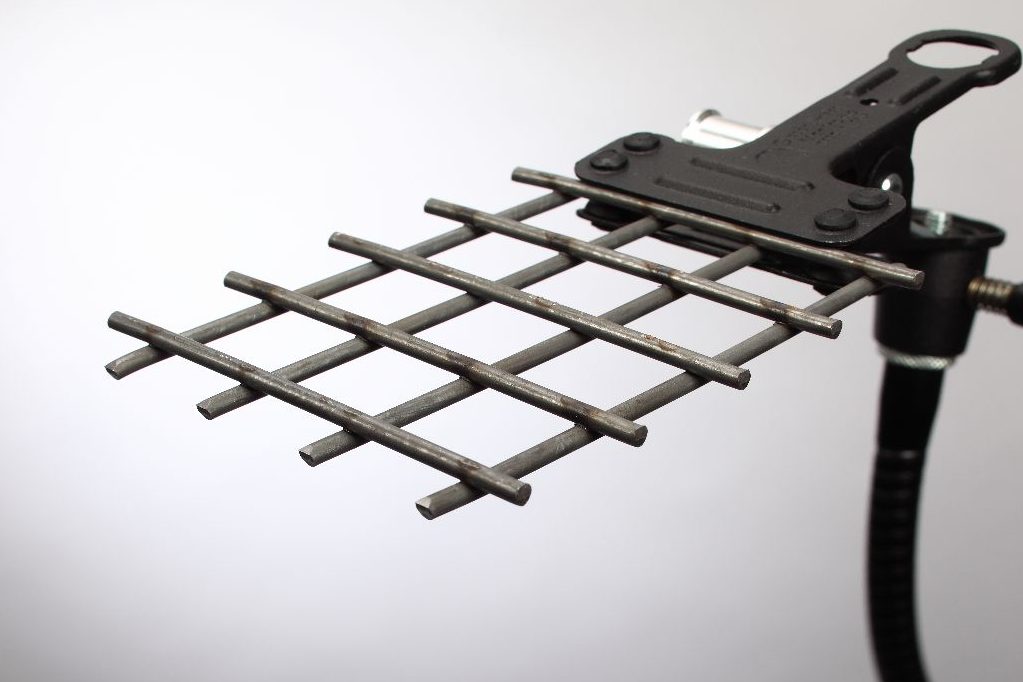

Welded Wire Meshes

We use multiple different strategies when welding together our wire mesh, including TIG, MIG, and Laser welding capabilities. These strategies are used when making our hardware cloth and standard welded mesh.

Hardware cloth is not cloth as its name suggests, but a type of welded mesh manufactured from galvanized steel wire. It is used for coarse sieves, animal cages, and other kinds of DIY projects around the home and garden.

Welded wire mesh is constructed from rigid wires welded at every intersection to provide a very stable and uniform surface. By welding rather than weaving, the material holds its shape well without supports, allowing shearing, rolling, and framing to be done with relative ease.